Directindustry

FMTG Cables and Sensors

FMTG cable brand established by FMT global . Our manufacturing facility in India developing high quality temperature cable and

sensors for all types of applications and meeting the most severe standards. We design and manufacture these products according to the customer’s individual needs in order to make sure that they accomplish company-specific norms. We are fast and can easily manufacture according to customer specifications and special requirements.

Product Description

Our range of products include:

- FMTG thermocouple grade extension & compensating cables

- FMTG heat tracing cable

- FMTG ptfe insulated wires & cables

- FMTG ptfe insulated shielded & screen instrumentation cables

- FMTG fiber glass insulated heavy duty cables.

- FMTG temperature sensors

- FMTG high temperature ceramic sheathed platinum thermocouple up to (1800deg )

- FMTG sheathed thermocouple -(1200 deg)

- FMTG mineral insulated thermocouple

HIGH TEMPERATURE CABLE

We manufacture high temp cable and thermo couple cable to accommodate all industry essentials. Among our collection of high temperature cable, thermocouple wire provide greater performance for technologically advanced industries. Our high temperature cables, intended for demanding environments. FMTG cable offers a large range of equipment wires insulated with PTFE, fiber glass etc. & metal shielding of SPC, TPC, SS etc. High temperature cable and thermocouple wire is resistant to chemicals, and excellent in high temperature applications. Certain thermocouple wire types even have the capabilities to withstand environments up to 1204°c., thermocouple wire continues to be a popular high temp wire because of its exceptional electrical and physical features.

All of our products are engineered and manufactured with strict quality control and designed for critical performance in today’s demanding environments.

THERMOCOUPLE TEMPERATURE SENSOR

A Thermocouple is a sensor used to measure temperature up to 1800 °C. There are many types of thermocouples, each with its own unique characteristics in terms of temperature range, durability, vibration resistance, chemical resistance, and application compatibility.

Types of Thermocouples:

Before discussing the various types of thermocouples, it should be noted that a thermocouple is often enclosed in a protective sheath to isolate it from the local atmosphere. This protective sheath drastically reduces the effects of corrosion.

1.Type K Thermocouple (Nickel-Chromium / Nickel-Alumel): The type K is the most common type of thermocouple. It’s inexpensive, accurate, reliable, and has a wide temperature range.

Temperature Range:

2. Type J Thermocouple (Iron/Constantan): The type J is also very common. It has a smaller temperature range and a shorter lifespan at higher temperatures than the Type K. It is equivalent to the Type K in terms of expense and reliability.

Temperature Range:

Temperature Range:

Temperature Range:

Temperature Range:

NOBLE METAL THERMOCOUPLES (Type S,R, & B):

Noble Metal Thermocouples are selected for their ability to withstand extremely high temperatures while maintaining their accuracy and lifespan. They are considerably more expensive than Base Metal Thermocouples.

Temperature Range:

Extension wire, 32 to 392F (0 to 200C)

Temperature Range:

Extension wire, 32 to 392F (0 to 200C)

Temperature Range:

TERMOCOUPLE ORIGINAL WIRE

Product Description

Construction -Single or Multiple Pairs

Voltage Grade – Up to 1100 V

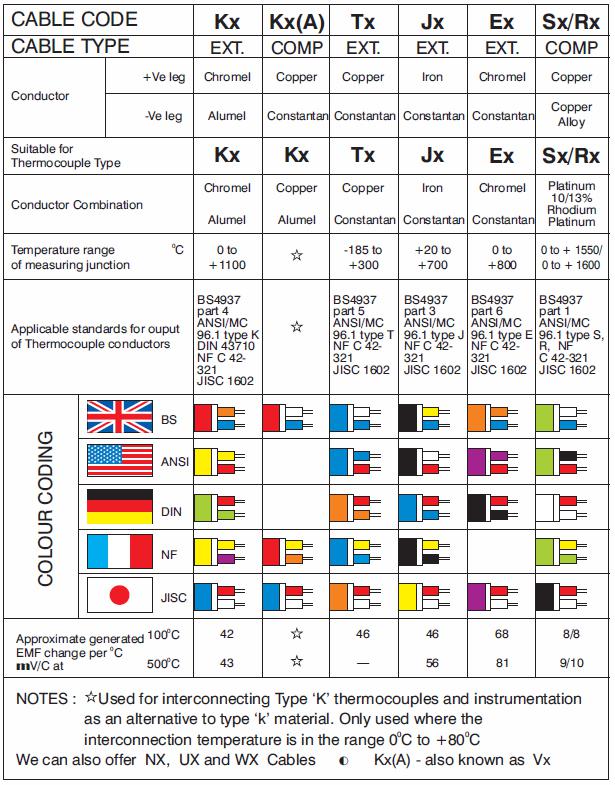

Cable Code – Kx,Kx(A), Tx,Jx,Ex,Sx / Rx,Bx,Nx,Ux,Wx

Range – 16 AWG / 18 AWG / 20 AWG up to 48 Pair

Primary Insulation – General purpose PVC / HEAT RESISTANT PVC / LDPE / XLPE / PTFE / Fibre Glass / FEP / Silicone Rubber

Screening – Individual and/or overall with following options – – Aluminum Mylar/Copper Tape with Tinned Copper Drain Wire or – Braided with Bare or Tinned or Nickel Plated or Silver Plated Copper

Inner Sheath – PVC / HRPVC / FRPVC / FRLS PVC/ ZHFR / LSF / PTFE / Fibre Glass

Armoring – GI round Wire / Flat strip or Wire Braiding

Outer sheath – PVC / HRPVC / FRPVC / FRLS PVC / ZHFR / LSF / PTFE / Fibre Glass

Rip cord – For easy removal of sheath

Standards – ANSI:MC-96.1, IS-8784, DIN, BS & IEC 584-3

Note: Other conductor sizes and insulation materials on request

| Type | Singles | Normal Operating Temperatures |

|

J |

Iron (JP)/ Constantan(JN) |

-350-1500°F |

|

K |

ChromelP(KP)/Alumel(KN) |

<-454-2000°F |

|

T |

Copper(TP)/ Constantan(TN) |

-454-600°F |

|

E |

ChromelP(EP)/ Constantan(EN) |

-454-1600°F |

|

N |

Ni Cr Si Ni SI |

-454-2372°F |

Technical Data

|

LOOP RESISTANCE (MAX) FOR THERMOCOUPLE CONDUCTORS at 20ºC OHM / Km. |

|||||||

|

THERMOCOUPLE TYPE |

KX |

VX |

TX |

JX |

EX |

RX/SX |

|

|

20 AWG Conductor |

1910 |

980 |

980 |

1214 |

2312 |

280 |

|

|

18 AWG Conductor |

1212 |

624 |

624 |

772 |

1470 |

175 |

|

|

16 AWG Conductor |

746 |

385 |

385 |

475 |

905 |

110 |

|

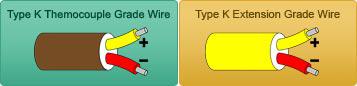

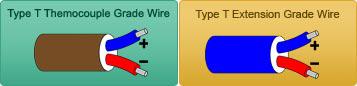

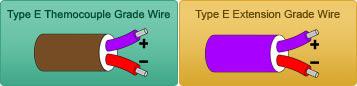

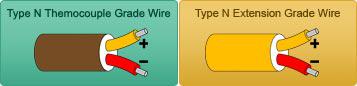

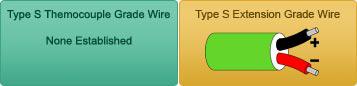

FMTG THERMOCOUPLE GRADE EXTENSION & COMPENSATING CABLES

Used for carrying data signals generated by thermocouple to the control panel

|

Type |

Conductors |

ANSI Color Coding |

IEC 584-3 Color Coding |

Temperature Range |

Comments |

||||

|

(+) Leg |

(-) Leg |

TC Grade |

Extension Grade TC |

TC Grade |

Intrinsic. Safe |

Min |

Max |

||

|

J |

Iron |

Constantan |

-210°C / -346°F |

1200°C / 2193°F |

Reducing, vacuum, Inert. Limited use in oxidizing at high temperatures. Not recommended for low temperatures |

||||

|

K |

Chromel |

Alumel |

-270°C / -454°F |

1372°C / 2501°F |

Clean oxidizing and inert. Limited use in vacuum or reducing. Wide temperature range, most popular calibration. |

||||

|

T |

Copper |

Constantan |

-270°C / -454°F |

400°C / 752°F |

Mild oxidizing, reducing vacuum or inert. Good where moisture present. Low temperature & cryogenic applications |

||||

|

E |

Chromel |

Constantan |

-270°C / -454°F |

1000°C / 1832°F |

Oxidizing or inert. Limited use in vacuum or reducing. Highest EMF change per degree. |

||||

|

N |

Nicrosil |

Nisil |

-270°C / -450°F |

1300°C / 2372°F |

Alternative to Type K. More stable at high temps. |

||||

|

R |

Copper |

Alloy 11 |

– |

-50°C / -58°F |

1768°C / 3214°F |

Oxidizing or inert. Do not insert in metal tubes. |

|||

|

S |

Copper |

Alloy 11 |

– |

-50°C / -58°F |

1768°C / 3214°F |

Oxidizing or inert. Do not insert in metal tubes. Beware of contamination. High temperature. |

|||

|

B |

Platinum- 30% |

Platinum- 6% Rhodium Pt- 6% |

– |

0°C / 32°F |

1820°C / 3308°F |

Oxidizing or inert. Do not insert in metal tubes. Beware of contamination. High temperature common use in glass industry |

|||

PTFE INSULATED WIRES & CABLES

PTFE Insulated wires and cables are divided into six sub-groups according to the construction and applications. The common features are:

PTFE Insulated wires and cables are divided into six sub-groups according to the construction and applications. The common features are:

Conductors

- Silver Plated Copper (SPC) for use up to 200°C (minimum 1 micron silver coating as per ASTM-B-298)

- Nickel Plated Copper (NPC) up to 260°C (minimum 1.25 micron nickel coating as per ASTM-B-355)

- Silver Plated High Strength Copper Alloy (SPHSCA) for mechanical strength in fine cross-sections and for superior flex-life (somewhat lower conductivity than copper) generally as per ASTM-B-624

- Pure Nickel for use up beyond 260°C; very high resistance to corrosion; DC resistance about 6 times that of copper at 20°C

- Resistance alloys for Thermo-Couple applications

- Silver Plated Copper Clad Steel (SPCCS) commonly used for RF coaxial cables) as per ASTM-B-501

- Spiral multi-strands on glass-fibre cord for high linear resistance — generally for heating applications

- Plain copper or Tinned copper can not be used due to high-temperature processing and applications; tin melts and flows into the interstices of stranding to make the conductor inflexible; copper tends to oxidize and become brittle

Sizes/Strandings

- Single strands from 0.05 to 1.02 mm (0.002″ to 0.040″), or more

- 7, 19, 37, 61 true concentric strands, or 133 strands rope-lay (19 x 7)

- Even AWG sizes from AWG 34 to AWG 6 (AWG 4 under development)

- Odd AWG sizes and other type of strandings/bunchings also available

- Integrated conductor facilityensures tighter control on resistance, diameter, finish etc.

- For further details, please refer to size table

Insulation/Dielectricis always PTFE (Poly Tetra Fluoro Ethylene CF4) which is the safest, cleanest, and most stable fluoro-carbon. Click here for Properties of PTFE. Multi-lap tape-wrapped sintered for

- 250 V AC RMS (so called Type ET with nominal 0.17 mm radial wall thickness in 3 layers

- 600 V AC RMS (Type E, 0.25 mm – 0.010″ – nominal radial wall)

- 1000 V AC RMS (Type EE, 0.38 mm – 0.015″ – nominal radial wall)

- For further details, please refer to size table

Compounded PTFE for High Voltage Cables; Sandwiched Polyimide (Kapton ®) Film for protection of PTFE from radiation.

Colours are 10 standard electronic as per MIL-STD-104, plus shades and stripes; details here

Metal Shields/Sheaths

- Round wire silver plated copper (SPC) or nickel plated copper (NPC)

- SPC or Plain Copper Flat Foil

- SS wires

Shielding methods

- Braided

- Served for lower overall diameter, especially for triaxial constructions

- Aluminised Polyester Film with drain wire (not compatible with PTFE jackets)

- Combination of Flat foil with round wire braid or Aluminised Polyester with round wire braid

Jackets/Outer Coveringsover shields are mainly of PTFE (upto 12 mm OD); larger sizes are difficult with PTFE. PVC or Silicone Varnished Fibre Glass or Polyurethane are available for such cases (or otherwise).

Armour (for armoured cables): Galvanized steel round wire / strip

Outer sheath: PVC – HR / FR / FRLS; PE, LSZH

FIBER GLASS INSULATED HEAVY DUTY CABLES

Our high quality Fibre Glass Insulated Copper Cable is widely used for ovens & heater lead wire applications. These cables are highly admired in the market for their high flexibility, higher cut-through, abrasion resistance and high working temperature. Moreover, we can customize these cables as per clients’ exact preferences and requirements.

Applications:

- Fibre glass cable for small electric motor and pumps

- Automotive Fibre glass application

- Heavy furnace wiring & heavy duty motors

- Home appliance wiring

- Heater wiring

- Oven wiring

- Fibre glass cables for alternators & generator

- Fibre glass cables for lighting & luminaries

- Industrial furnace wiring

- Various electrical applications

- Asbestos heatproof cables

- Heating element mfg

- Heating systems mfg

- High temperature resistant systems

RTD CABLES

RTD CABLES are used to transmit signal from RTD SENSOR to control Unit .RTD Cables are made in 2 core, 3 core, 4 core and 6 core configurations, 3 cores being the most commonly used configuration.

| Conductor | Electrolytic grade silver plated copper, nickel plated copper, tin plated copper wires. |

| Core Insulation | As per the table i.e. PTFE / FIBER GLASS / CERAMIC / SILICA YARN / KAPTON SILICON |

| Core Laying | Cores twisted together |

| No. of Pair | 1, 2, 3 or more |

| Screening | Silver plated copper wire, Tin plated copper, Bare Copper or SS as per client’s requirement. |

| As per the table i.e. PTFE / FIBER GLASS / CERAMIC / SILICA YARN / KAPTON SILICON | |

| Braiding | Fine annealed soft mirror finished SS WIRE |

| Armoring | GI Round Wire wire / strip for PVC |

| Color Coding | As per DIN 43760 or as per client’s requiremen |

| CORE INSULATION | SHEATH INSULATION | MAX. TEMP. | INSULATING MATERIAL CHARCTERISTICS |

| PTFE TAPPED | PTFE | 250 °C | Resistant to Abrasion, oil, moisture etc with high electrical & mechanical properties. |

| FIBER GLASS BRAIDED | FIBER GLASS | 400 °C | Good temperature resistant |

| CERAMIC YARN BRAIDED | CERAMIC YARN | 800 °C | High Temperature Resistant |

| SILICA YARN BRAIDED | SILICA YARN | 1200 °C | High Temperature Resistant |

| SILICONE EXTRUDED | SILICONE RUBBER | 200 °C | Excellent flexibility with good temperature resistant. |

| KAPTON TAPPED | KAPTON | 310 °C | Thin Insulation, temperature resistant |

| PVC | PVC | 70 °C | Versatile for normal application |

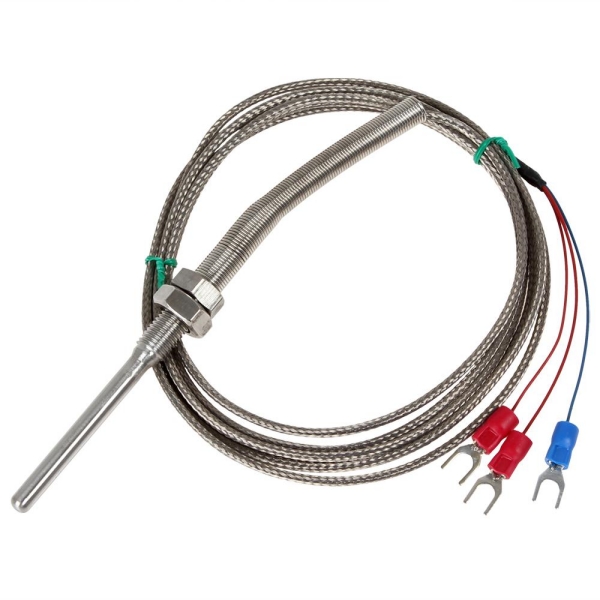

TEMPRATURE SENSOR THERMOCOUPLE

THERMOCOUPLES are designed to suit various applications. Thermocouple assemblies are generally used to measure temperature up to 1800 °C.

TYPES OF THERMOCOUPLE :

• Bayonet Thermocouple Assemblies of various types up to 600 °C

• Sheathed Thermocouple in various sizes for temperature applications up to 1200 °C.

• High Temperature Ceramic Sheathed Thermocouple for applications up to 1800 °C.

• Mineral Isulated Thermocouple assemblies for sponge iron & other industrial application

Bayonet Thermocouple Assemblies:Bayonet Thermocouple Assemblies in standard calibration such as J Type, K type etc.

• Various types such as Straight, L Shaped, Spiral, Washer, Screw & Bolt type

• Length in 1 Mtrs., 2 Mtrs., 3 Mtrs. etc. as per requirement

• Mainly used in Plastic Molding Machinaries, Textile & Pharmaceutical Industries.

Mineral Insulated Thermocouple :Mineral Insulated Thermocouple assemblies manufactured from the best quality MI Cables.

• Compact insulation of high purity MgO, Alumina, Hafnia Oxide.

• Protection Sheath: SS 316 / SS 310 / Inconel 600 etc.

• QRT Type MI Thermocouple with Male Female Connector

• Configuration: Simplex, Duplex

• Available in various sizes from 1.5 to 8mm.

• Fast Responding & durables

• Protection Sheath: SS 304 / SS 316 / SS 310 / Inconel 600 / HRS 446 Ceramic etc. depending upon temperature & applications.

• Configuratin: Simplex, Duplex, Multi Point

• Process Conn.: Screwed or Flanged

• Enclosore: Alu. Die Cast Head to IP 65 / IP 67

• Temp. Rnage: Designed for Temp. Range up to 1800 °C

• Protection Sheath: Ceramic KER 710 / 610

• Configuratin: Simplex, Duplex, Multi PointProcess

• Conn.: Screwed or Flanged

• Enclosore: Alu. Die Cast Head to IP 65 / IP 67

RTD Sensors :

Remote Temperature Detection Sensors are high precision devices used to measure temperature in corrosive & non corrosive media. They are used to measure temperature from -400 °C to 600 °C. They are unequal in performance. Stability over long period of continued use makes them unmatched for reliability.

• RTD are high precision devises used to measure temperature in corrosive & non corrosive medium.

• 2 Wire / 3 Wire / 4 Wire / 6 Wire as per customer’s specifications.

• Designed for applications from -150 °C to 650 °C.

• Used extensively in textiles, chemicals, pharmaceutical and processing industries

| Element | RTD: 2 Wire / 3 Wire / 4 Wire / 6 Wire -150 – 600 °C |

| Sheath Material | SS 304 / SS 310 / SS 316 or as per customers’ specifications. |

| Insulation | Mineral / Ceramic |

| Element | Simplex / Duplex / Triplex |

| Termination | Flame Proof or Weather Proof Head with Single, Double entry from Cast Aluminum / Cast Iron / SS / Plastic Seal Pot with flying leadsSeal Pot with Male / Female Connectors (QRT)Ceramic Terminal Block with SS Base Plate SS Base Plate with flying leads for Temperature Transmitter |