Hydro Dynamic Bearings and Seals

FMTG provides its Manufacturing services to Both: Original Rotating Equipment Manufacturer (OEM) & The End User

Product Description

FMTG provides its Manufacturing services to Both: Original Rotating Equipment Manufacturer (OEM) & The End User

Materials: All of our Whitemetal Lined components are manufactured or repaired using virgin whitemetal (Imported from EU)

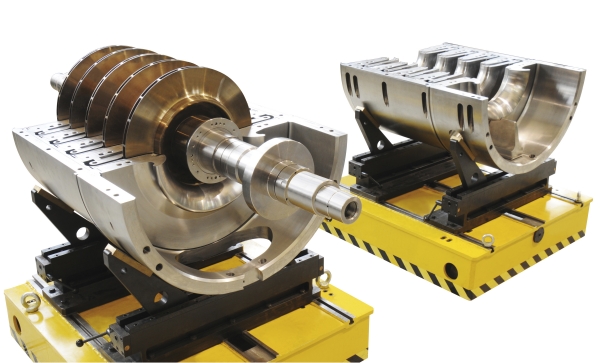

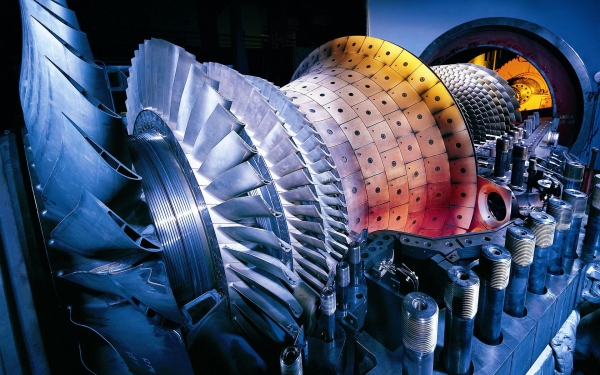

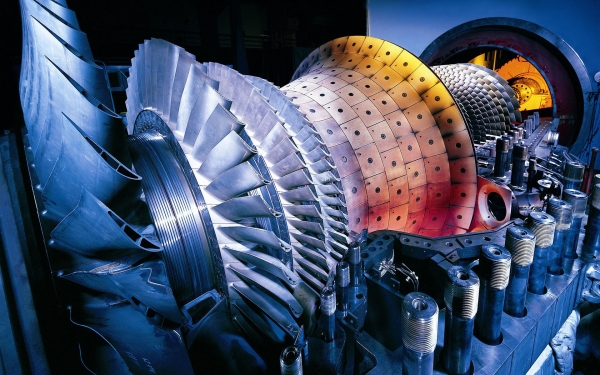

FMTG DESIGNS, MANUFACTURES & REPAIRS WHITEMETAL LINED BEARINGS FOR INDUSTRIAL ROTATING EQUIPMENT

- Turbine Bearings

- Generator Bearings

- Compressor Bearings

- Motor Bearings

- Gear box Bearings

- Pump Bearings

- Diesel Engine Bearings

- Fan Bearings

WE ARE ABLE TO OFFER BOTH MANUFACTURE & REPAIR CAPABILITIES FOR WIDE VARIETY OF COMPONENTS INCLUDE

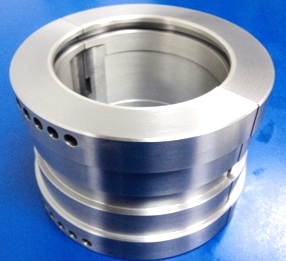

- Journal Bearings

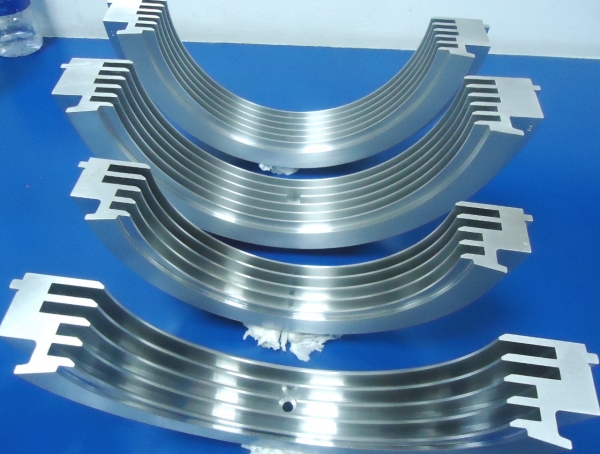

- Thrust Bearings

- Combined Journal & Thrust Bearings

- Thrust Pads

- Journal Pads

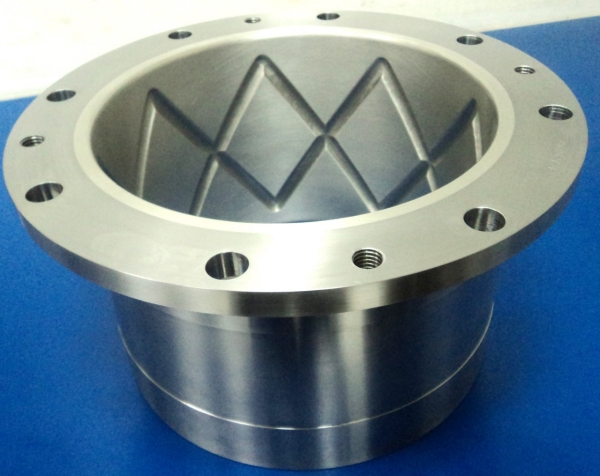

- Generator End Caps

- Oil Deflectors

- Cross head Slides

- Hydrogen Seals

- Seal Rings

- Oil Seals , Etc

MANUFACTURING:

We can manufacture parts up to 50mm diameter motor bearings.

To:1200mm diameter steam turbine bearings diameter from simple sleeve bearings to complex combined tilt pad journal and tilt pad thrust bearings.

Reverrse Engineeirng: We offer reverse engineering services for any kind of hydrostatic and hydrodynamic bearings(white metal bearings) it's assembly components and rotating equipment parts .As long as a sample or drawing is provided. We can deliver standard and custom products that fit your applications and requirements.

We can work to any design, material and order quantity.All items can be supplied with the following certification:

- Dimensional inspection

- Ultrasonic testing

- Dye penetrant testing

- Material test certificate

REPAIR: FAST, COST EFFECTIVE

Our experience covers all type of hydrostatic and hydrodynamic bearings and almost all bearing parts can be repaired. We support clients with very short turn around and often combined with re-engineering and supplying a spare for future use.

FMTG have Stringent quality check points at every stage of bearing's refurbishment process, to make sure we are delivering products to best standard

ENGINEERING AND TECHNICAL SUPPORT

We are committed to being very aggressive in our attitude toward quality and customer services. All functional dimensions of the bearings are recorded using highly advanced coordinate measuring machine and other advanced quality check instruments

- Whitemetalling Technology- Centrifugal Casting, Static Casting, Tig Welding, Re-Metalling, Fluxing and tinning

- Bearing Failure Analysis

- Onsite NDT inspection

- Large drawing data base

- 365 Days technical and engineering supports

- Best lead time with enough white metal readily available in our inventory

INFRASTRUCTURE

Well-Furnished facility with most advance machinaries required to provide you with the best quality solutions for your hydro dynamic bearings.

Machining Capability

- Leadwell CNC Milling – 2m x 4m bed

- Dugard CNC Milling – 1m x 800mm bed

- Dugard CNC milling – 1m x 2.2m bed

- Hatford CNC milling – 1m x 550mm bed

- Cincinnatti CNC Lathe – max dia 200mm, 650mm long

- Doosan CNC Lathe – Max 400 x 400mm long

- Doosan CNC Lathe – Max 800x 2000mm long

- Leadwell CNC Lathe – Max dia – 120mm – 60mm long

- HMT CNC Lathe – Max Dia – 250mm x 1.5m long

- Flow Water jet cutting machines – 3 numbers – 3m x 4m bed

- Conventional Lathe – TRENS – 400mm dia, 4m long

- Conventional Lathe – SMTCL – 1500mm dia, 3m long

- Conventional Lathe – 1000mm dia, 2m long

- Achtung Horizontal boring machine – 1.5m x 1.5m bed

- Other small conventional lathe and milling machines for smaller jobs

- Radial Drilling machine

Facilities

- UAE

- SAUDI ARABIA

- UK